Cocciopesto Deumidificante MGN

Our premium dehumidifying system

An original Roman recipe. Excellent humidity regulator, improving the air quality of cellars, shower rooms and other humid environments

Typical applications: to dehumidify damp masonry in the presence of capillary rising damp, even of high intensity, strong salt concentrations, marine environments, restoration and renovation of historical buildings, barn conversions and farm buildings.

Cocciopesto Deumidificante MGN is a dehumidifying system consisting of two products: Rinzaffo MGN + Cocciopesto Deumidificante MGN capable of resisting salts, (sulphates, chlorides and nitrates), which would attract moisture in the masonry, eroding and ruining it, eventually.

Sulphates are typically yellow salt deposits around fire places, chimneys or sulfur gases washed into the buildings by rain in polluted big cities.

Chlorides come from seawater, mist, fog, rising damp and frost prevention of the roads by salts, or from modern cement coats.

Nitrates are typical in farm environments and essentially are decomposed waste matter, manure or fertilisers.

Roman Waterproofing

in a Grade I Listed Church

Cocciopesto plasters can be found in many archaeological areas and historic buildings all over Europe as the Romans “exported” and used cocciopesto plasters throughout the former Roman Empire.

The lightness and elasticity makes this mix capable of supporting large thicknesses and movements of masonry, thus providing an ideal substrate for fine finishes, based on natural lime.

In this video you can see how to apply, how it feels and looks like.

Why replace something perfect with new?

We vote for Cocciopesto against modern plasters

It is based on the ancient concept that the porosity of the lime and crushed terracotta give the product high vapour permeability and an exceptional ability to regulate the humidity of the masonry.

Milled terracotta or brick (in Italian: cocciopesto) was the solution for acquiring dryer and warmer buildings, in the antique times.

Earthenware plasters had been used extensively in Roman heating plants due to their ability to accumulate heat and absorb the moisture from hot flue gases.

Cocciopesto plasters have been in use since about 500 BC, traditionally made of pure slaked lime mixed with crushed tile or brick powder.

Initially a Phoenician plaster was adopted by the Romans, proven extraordinary success in the construction of aqueducts, Roman Baths, roads and underfloor areas.

Ancient Roman underfloor heating system: Hypocaust

Oxfordshire, UK

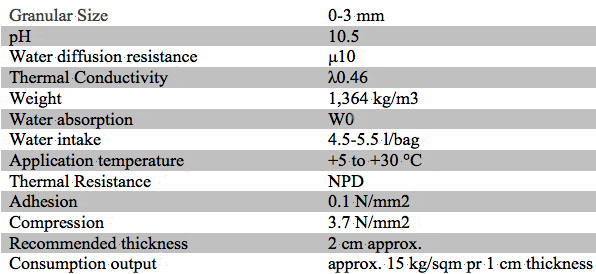

Specifications

Composition

- Hydrated lime, with more than 90% calcium hydroxide (CL90S as per EN459-1 standard)

- NHL3.5 natural hydraulic lime (UNI EN 459-1)

- Brick powder / crushed bricks (cooked at low temperature, 0-3 mm)

- Volcanic soils – pozzolans (per UNI EN 197-1)

- Natural additives to improve workability

Colour: antique rose

or Contact us

Thank you for getting to this point, we appreciate your interest in our solutions.

You can simply place your order using the form below or get in touch.

Whether over the phone or in email correspondence, the first consultation with our surveyors is free of charge, no obligation.

Professional Building Survey is available as well all over UK, typically for £390+VAT, with a little surcharge if the property is at a very secluded place.

Interested? Please feel free to reach out we are here for you