Cocciopesto MGN

Ancient Roman humidity regulator and heat resistant plaster

since ca. 500BC, for internal and external use

Typical applications: humid, non-salty environments, e.g. bathrooms or external renders, eco buildings, wooden, thatched, hemp block constructions. Very gentle to the building fabric.

– A 100% natural and breathable/porous humidity regulator for external and internal works

– Strong humidity regulator and anti-mould

– A great choice of plaster for bio buildings, too

– Gentle to the building fabric: suitable for plastering soft materials, such as wattle and daub or timber frame construction

– Its stable and even colours, ranging from yellow ocher to light red, are holding up longer than painted plasters.

Cocciopesto plasters can be found in many historic buildings throughout Europe as the Romans have “exported” and used this plaster all over the former Roman Empire.

The lightness and elasticity makes this mix capable of supporting large thicknesses and movements of masonry, thus providing an ideal substrate for fine finishes, based on natural lime.

In this video you can see how to apply, how it feels and looks like.

Mr Naldo Busato

CEO of MGN, MASTER CRAFTSMAN

Meet Our Adviser

Mr Naldo Busato – from the video above – is a Venetian Building Restoration Master Craftsman, the last link of a multi-generation guild tradition of Venice. Leading researcher of Roman Architecture and Roman building materials.

Please see a project of historical importance where Cocciopesto plaster was applied.

Rebuilding

Teatro La Fenice

How is Cocciopesto produced?

The process starts with firing limestone in large kilns, at 850-900 C temperatures, and as a result, limestone turns into a powder: quicklime. If you add water gradually to quicklime, it’s transforming into the soft and white lime putty, while exerting strong heat and steam.

Now add powdered bricks or terracotta (essentially clay shards) instead of sand. These mixes are referred to as “Cocciopesto” by today’s Italian Masters.

Adding either or both, the result is a quickly setting mix.

Romans extensively applied these plasters in very demanding environments, e.g., sewers, ports, spas, and aqueducts.

For structural waterproofing they preferred to replace sand in the mix with Pozzolans – the mixes with volcanic ashes see at Rinzaffo MGN – and Cocciopesto.

Thus developing extreme strength, while retaining the breathability of lime putty plasters. E.g. in harbour works, basements and foundations.

These Cocciopesto Plasters are popular ever since, in the world heritage site of Venice, the Venetian Lagoon, partly due to their aesthetic virtues.

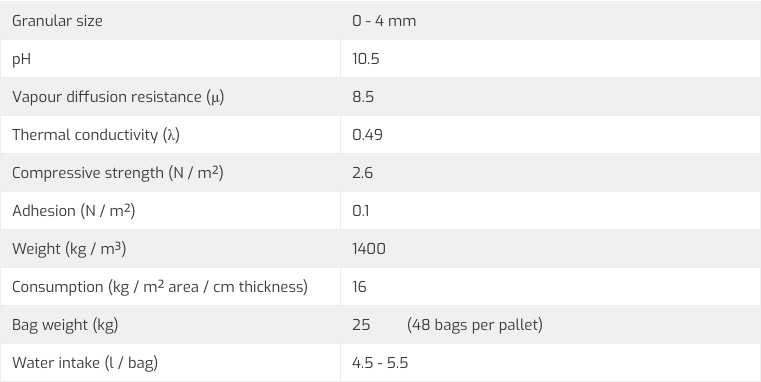

Specifications

Composed of

- Hydrated lime, with more than 90% calcium hydroxide (CL90S as per EN459-1 standard)

- NHL3.5 Hydraulic lime, desalinated white

- Brick powder / crushed bricks (cooked at low temperature, graded 0 – 4 mm)

- Pozzolans

- Marble powder

Colours from yellow ocher to pale brick, adjustable by the different types of brick powder

or Contact us

Thank you for getting to this point, we appreciate your interest in our solutions.

You can simply place your order using the form below or get in touch.

Whether over the phone or in email correspondence, the first consultation with our surveyors is free of charge, no obligation.

Professional Building Survey is available as well all over UK, typically for £390+VAT, with a little surcharge if the property is at a very secluded place.

Interested? Please feel free to reach out we are here for you