Controlling Indoor Humidity with Lime Plasters

Above and below ground applications

Charming stone cottage in Wales.

St. Michael’s Abbey, Grade I. Listed Crypt Project

Humidity Management in Above-Ground Structures

Using Roman Lime Plasters

Traditional Stone Cottage

This charming stone cottage in Wales was restored with one clear objective: to create a healthy environment resistant to humidity-related issues. By using a compatible lime plastering system specifically designed to perform in spaces prone to humidity problems, the cottage will remain free from condensation and mould — even when closed up for long periods during humid weather.

🎥 Watch the video and see the details of the project, below

The restoration relied entirely on a breathable, lime-based solution — a technique widely used in Ancient Rome to regulate indoor humidity in Roman baths and marine environments.

When it came to preventing condensation and controlling indoor humidity, the Romans turned to a material called cocciopesto (an Italian term for lime–terracotta plaster), known in Ancient Rome as opus signinum.

This material possesses several remarkable properties:

Composed of breathable lime and crushed terracotta or brick fragments, both the binder and the aggregate are vapour-permeable, allowing the material to absorb humidity from the air more effectively than almost any other.

Even when humidity levels rise temporarily, condensation does not form on its surface.

It is a naturally warm material, maintaining a comfortable surface temperature even in humid environments.

Project Details

- The base coat used throughout is a 15mm layer of Rinzaffo MGN, a Roman, moisture- and salt-resistant lime base coat. It was applied not only as a base plaster but also for all pointing and masonry repairs, ensuring that any damp or lateral moisture penetration is stopped before reaching the subsequent coats.

- External walls, requiring thermal insulation, were finished with approximately 25 mm of Coccioterm plaster — a lime-and-terracotta insulating plaster with excellent moisture-buffering properties. Coccioterm can absorb and release significant amounts of humidity without visible damp patches or creating conditions for mould growth. Essentially, it forms a breathable envelope around the cottage, keeping it warm and dry throughout the year.

- Internal walls received a 12mm coat of Cocciopesto Deumidificante, a lime–terracotta dehumidifying plaster (similar to Coccioterm but without the thermal aggregate). It was also applied over wood-wool stud walls — a far more humidity-tolerant option than conventional gypsum plasterboard — providing partitions with the same humidity-regulating properties and a uniform appearance.

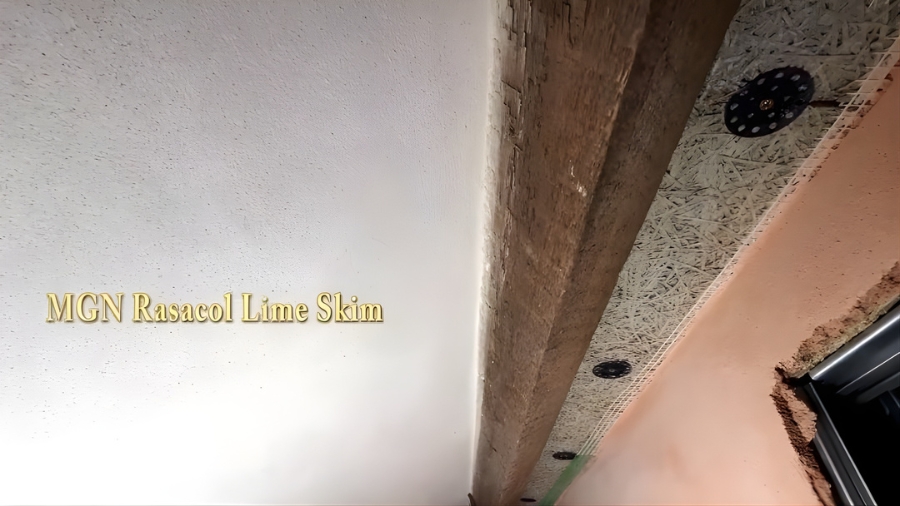

- Wood-wool ceilings were finished with Rasacol MGN, a fine, smooth lime-based finishing plaster that adheres beautifully to wood-wool boards, insulating panels, or plasterboard. The result is a cohesive interior finish that allows the entire structure to “breathe” naturally.

Simply by the use of these compatible materials, and natural ventilation, the cottage will remain free from condensation and mould — even when closed up for long periods in humid weather.

Subterranean Moisture Management

Using Lime Plasters

Heavy-duty lime waterproofing in a Grade I listed crypt

🎥 Video I – The problem and solutions

Our second case study takes us underground — into the challenging environment of a Grade I listed crypt suffering from persistent dampness and moisture ingress.

The crypt’s stonework restoration had already been completed, but as you can see in the first video, moisture remained a major problem. Behind one of the internal walls lay a small chamber that repeatedly flooded, allowing water to seep through the masonry and stain the crypt’s ornate carved stone walls.

To solve this, we employed a traditional Roman waterproofing method — a 100% conservation-friendly, lime-based solution. It’s impressive to see how well it works even in this challenging case, reminding us of the ingenuity of Roman architectural solutions.

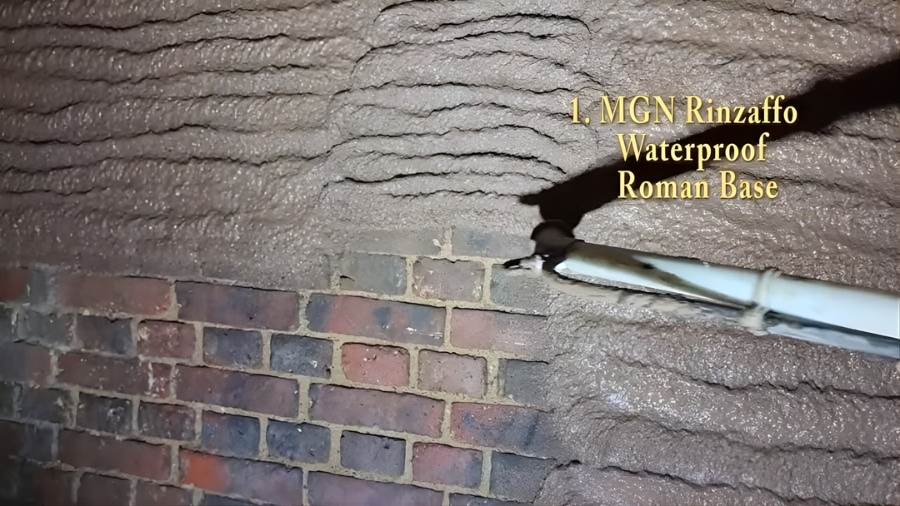

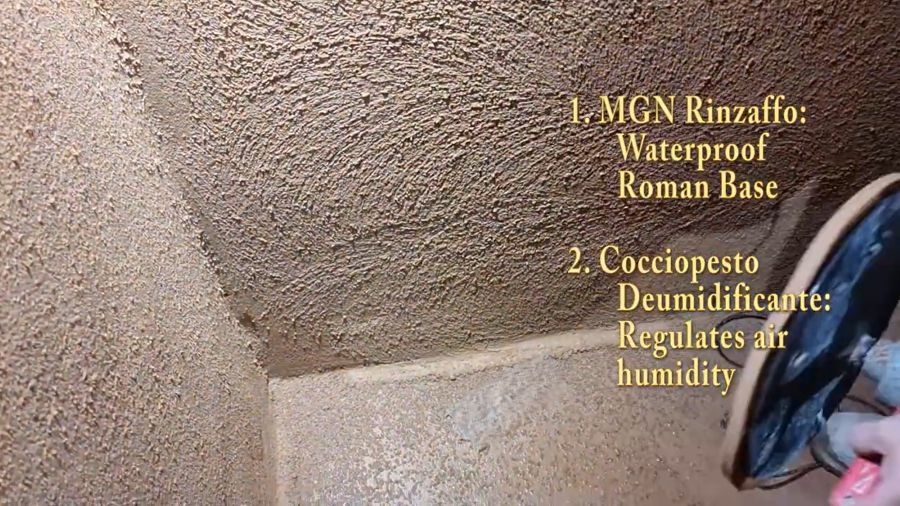

- The first material applied was two layers of 12 mm Rinzaffo MGN Roman Waterproofing Mortar — a lime mortar that is both breathable and highly water-resistant. When applied at this thickness, it can withstand lateral moisture ingress as well as hydrostatic pressure. It is ideal for waterproofing basements, vaults, and retaining walls where both breathability and durability are required.

- The second coat was Cocciopesto Deumidificante, the same humidity-regulating plaster used in the cottage project. It plays a vital role in maintaining balanced indoor humidity levels and offers superior moisture control compared with conventional lime mortars.

Once applied, the surface was floated using a power float, resulting in a clean, subtly rustic finish that complements the heritage setting.

About half a year later, we returned during a particularly wet period. Despite heavy rain and continuous damp conditions, the crypt remained perfectly dry — no water ingress, no damp stains, and no moisture on the floor.

This project not only preserved the historic fabric but also demonstrated how breathable Roman lime technology can provide lasting waterproofing without sealing the structure. It’s a reminder that, with the right materials and approach, even the dampest heritage spaces can be made dry, healthy and long-lasting.

🎥 Video II – Final results

Learn More About These Unique Products:

Roman Waterproofing Base Coat

Rinzaffo MGN Breathable, water-resistant base coat resisting rising and penetrating damp, keeps moisture and salts in check by turning liquid moisture into a regulated vapour flow.

Roman External/Internal Moisture Buffer

Coccioterm MGN Ancient Roman thermal and moisture-regulating plaster with high humidity buffering capacity. Coccioterm can absorb and release significant amounts of humidity without visible damp patches or providing conditions for mould growth.

Internal Dehumidifying Plaster

Cocciopesto Deumidificante MGN is a lime–terracotta dehumidifying plaster (without the thermal aggregate). Controls air humidity, prevents mould, ideal for humid spaces. Ancient Roman recipe.

Rasacol MGN

Fine finish coat / Skim

Rasacol MGN is Smooth, versatile finish compatible with wood wool, plasterboard, and insulation panels. A cohesive interior finish that allows the entire structure to “breathe” naturally.

Got Questions?

Planning Your Own Project?

Controlling Indoor Humidity with Lime Plasters Read More »