Lime Plastering in One Day

From Stripping to Decoration

In modern building restoration, time is always against us. Conventional lime plasters need long setting and drying times, which makes fast progress nearly impossible.

The solution? A technology rediscovered from the Ancient Romans — true masters at tailoring lime mortars to meet specific needs. They had one special ingredient that changed everything: volcanic pozzolans.

This allowed lime plasters to set quickly while maintaining — even improving — breathability. Thanks to this, plastering could be carried out from stripping to decoration in just a single day.

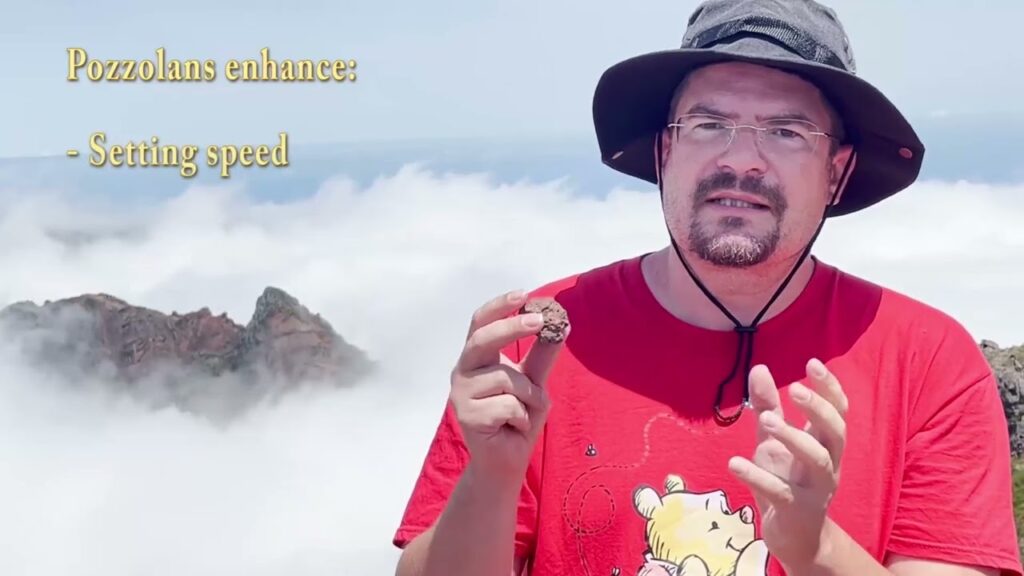

![]() Discover the secret ingredient: real volcanic pozzolans, the reason Roman mortars still hold together buildings that have stood strong for more than 2,000 years.

Discover the secret ingredient: real volcanic pozzolans, the reason Roman mortars still hold together buildings that have stood strong for more than 2,000 years.

How Roman Pozzolanic Lime Mortars Worked

The Romans first discovered, through observation, how pozzolans enhance the properties of lime mortars. Today, modern science not only confirms this but also explains the mechanisms behind it. Used in foundations, stone buildings, and major infrastructure, pozzolanic mortars are a key reason Roman architecture has endured for millennia.

Watch this video, where Mick explains what pozzolans are and how they improve the performance of lime mortars:

Key benefits of pozzolans in lime mortars:

- Faster setting speed

Greater mechanical resistance

Salt resistance

Excellent vapour permeability

Where the name comes from:

Pozzolan comes from Pozzuoli, a town near Mount Vesuvius, Italy. Volcanic material from this region — rich in aluminates and silicates — was ground and added to lime, creating a mortar that was:

-

Durable

resisting centuries of wear

-

Resistant

withstanding salts and harsh conditions

-

Breathable

keeping walls and structures healthy

The reddish, aluminate-rich fraction enabled rapid setting and chemical resistance, while the grey, silicate-rich fraction provided long-lasting mechanical strength. And because the aggregate itself was porous, the mortar became even more breathable than standard lime-sand mixes.

The outcome? A material both resilient and highly breathable — perfect for historic conservation and modern applications alike.

That’s the secret of Roman longevity, and the foundation of our structural grade and waterproofing lime mortars, designed to last for generations.

Have questions?

Practical Application: Lime Plastering

in 24 Hours

This video demonstrates a dehumidifying lime plastering system based on Roman pozzolanic technology. Thanks to the fast-setting properties of aluminate-rich lime mortars, the plastering process can be completed within 24 hours. The only limiting factor is the number of people on site, not the setting time.

Here is how the system works:

1. Apply Risanasmart MGN – a close relative of the Roman base coat Rinzaffo MGN (Risanasmart MGN is formulated to harden rapidly and engineered to prevent shrinkage by incorporating aggregates of varying sizes — down to the micron — in carefully balanced ratios.).

2. After 5–6 hours, once hardened, apply the Rasacol MGN aluminate-rich lime finish.

3. After another 5–6 hours, finish with lime wash or lime paint.

We tested this system in Italy with impressive results: from hacking off the old plaster to decoration, everything was finished within 24 hours.

LEARN MORE

click on a product

Rasacol Lime Finish

Flexible, non-cracking traditional lime finish